Liquid & Oil-resistant Safety Wheel Chocks

Wheel Chock for Utes and Small 4WDs

Card Number. 2840.00

Complies with standards for wheels up to 88.9cm in diameter and gross vehicle weight of 13 tonne

Wheel Chock Orange Urethane suitable for Utes and Small 4WDs - Sold Individually

- Tough Urethane construction

- Resistant to oils, fuels and solvents

- Recessed carrying handle

- High Vis orange colour

- Mounting hole for ropes, chains or brackets

- Mounting brackets available 2840.10

- Replaceable rubber anti slip traction pads

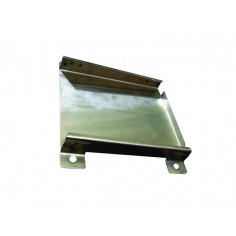

Wheel Chock Bracket

Card Number. 2840.10

Wheel Chock Bracket Stainless Steel suits 2840.00 - Sold Individually

Wheel Chock for Medium Trucks

Card Number. 2841.00

Wheel Chock Orange Urethane suitable for Medium Trucks. - Sold Individually

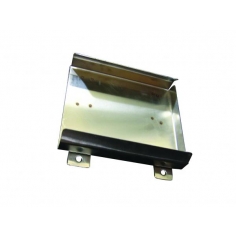

Wheel Chock Bracket Stainless Steel

Card Number. 2841.10

Wheel Chock Bracket Stainless Steel suits 2841.00 - Sold Individually

Wheel Chock for Trucks 10 to 15 Tonne

Card Number. 2844.00

Wheel Chock Orange Urethane suitable for Trucks 10 to 15 Tonne - Sold Individually

- For tires with up to a 116.8 cm outside dia.

- Rated for vehicles with a gross operating weight up to 27,216kg (81cm Dia) & 13,608kg (116.8cm)

- Weather-resistant, lightweight polyurethane construction

- Resistant to oils, fuels, and solvents

- Recessed carrying handle

- Mounting hole for ropes or chains

- High visibility orange color

Wheel Chock for Trucks 20 to 25 Tonne

Card Number. 2846.00

Heavy-duty, orange urethane durable wheel chock measuring 210 x 290 x 225 mm in size. Manufactured from a hard-wearing, moulded rubber, suitable for Trucks 20 to 25 Tonne. Featuring grips to keep the tyre from slipping and a built-in handle for easy carrying, this chock is rugged and lightweight. It also has holes for installation of ropes, chains, and/or mounting brackets. Great for commercial trucks, delivery trucks, service trucks, large tractors, and more.

Sold Individually

Proper Wheel Chocking Practices:

- ALWAYS chock wheels at the center point of the wheel. NEVER chock wheel at off-center or at an angle.

- Improper chocking can lead to the chock not working correctly and/or could lead to possible injury.

- ALWAYS position the wheel chock against the wheel so that it is making contact.

- If chocking on an incline or decline, chock the wheels accordingly based on the type of vehicle, weight, tire diameter/size etc. Consult full “Wheel Chock Guidelines” for more information.

- ALWAYS consider the surface/terrain and environment around the vehicle. Soft “Soil”, wet, or slippery terrain can affect the usability of wheel chocks and/or cause a potential for failure.

- ALWAYS use a minimum of (2) wheel chocks.

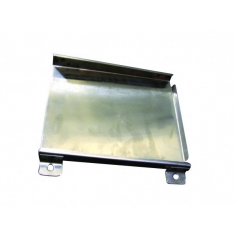

Wheel Chock Bracket Stainless Steel

Card Number. 2846.10

Wheel Chock Bracket Stainless Steel suits 2844.00 and 2846.00 - Sold Individually

Wheel Chocks for Trucks 10 to 110 Tonne

Card Number. 2852.00

Wheel Chocks for Trucks 10 to 110 Tonne - Sold Individually

Wheel Chocks for Trucks 70 to 725 Tonne

Card Number. 2855.00

Wheel Chocks for Trucks 70 to 700 Tonne - Sold Individually

Small Wheel Chock (W4) 140L x 100W x 80H

Card Number. 840.54

WC4

Material

Moulded Rubber

Manufactured from extremely durable and hard wearing EPDM blended rubber compound.

Description

140mm x 100mm x 80mm

Perfect for trailers & caravans. Hole through the centre for a rope tie-through.

Heavy-duty tyre chocks for utes, trucks and heavy machinery

Safety wheel chocks, also known as wheel blocks or tyre chocks, are essential pieces of equipment used to prevent vehicles from rolling while parked. Whether you’re just parking your work vehicle for the day or getting under the chassis to conduct repairs and maintenance, safety chocks are the critical last barrier that keeps the vehicle locked in its spot.

Ovesco’s heavy-duty safety wheel chocks are designed for use with all industrial vehicles, including utes, vans, trucks, trailers and heavy machinery. Their extreme slip resistance allows them to be used on inclines and uneven surfaces alike.

Browse our full range, and get in touch with our product specialists for recommendations and advice.

Why choose us?

Australia’s leading supplier of hardware

Ovesco has been built on selection and service. We take pride in being able to offer product solutions for any issue in the industrial and transport sectors. Better yet, we have the experience to offer qualified advice across the broad selection of items we supply. We know what it takes to meet your expectations.

4000 items

We have over 4000 high quality product lines available in hundreds of different categories.

20 years

We have over 20 years of experience servicing businesses in industrial and transport.

Expert Knowledge

How we meet customer expectations

Our staff are highly experienced tradespeople from an array of fields and offer reliable advice for all solutions in the industrial and transport sectors. Contact us by phone or send through an email enquiry and one of our qualified staff will contact you back to assist with the right solution.

FAQs

What are liquid & oil-resistant safety wheel chocks?

Liquid & oil-resistant safety wheel chocks are devices designed to prevent vehicles or equipment from moving accidentally. These chocks are specifically treated or made from materials that resist degradation when exposed to liquids, oils, and chemicals.

How do liquid & oil-resistant safety wheel chocks work?

How should liquid & oil-resistant safety wheel chocks be maintained?

Have a question?

Contact us

Want to know more about our products? Leave a message and a member of our team will be in touch.